Lean Management

Lean management involves more than just the well-known – at least by definition – lean manufacturing. Here the lean idea is rolled out to the whole company which also includes the office areas. In the lean management analysis, waste and overload (man and machine) are determined in particular.

The insights gained will eventually simplify operations, accelerate them, and eliminate unnecessary resource expenditures. In manufacturing companies, Lean Manufacturing is usually started in production. Here, the best and most easily achievable results in terms of effectiveness and efficiency are expected.

Lean Manufacturing is an important building block for the operational excellence of a company. As is well known, this is true for mass producers – but also for single-tailors alike.

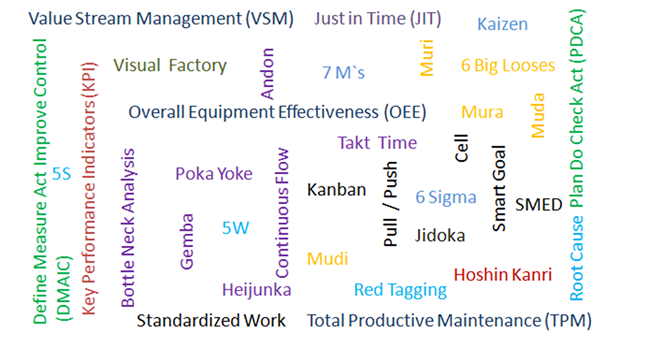

If you are faced with the task of introducing lean management / manufacturing in a company or continuously improving it, you can counter all sorts of keywords or lean tools:

Especially with the introduction and the further development of the company-internal lean approaches these buzz words may confuse. All the more you need a good compass or neutral mediator, which helps to find the right measures – to quickly, easily and accurately determine the important Quick Wins or the Low Hanging Fruits.

For the further development and continuous improvement of the lean system motivated, trained and convinced employees are needed. The employees are trained by us and actively involved in all measures. Continuous improvement should not be a flash in the pan, but a philosophy or simpler: lean should become a significant and sustainable value for the company, which is supported by its employees.